In the modern construction industry, one of the biggest challenges is ensuring that buildings remain energy-efficient while providing occupants with comfort. Rising electricity bills and the global push toward sustainability have made energy-saving building materials a necessity rather than an option. Among the most effective solutions are PUF (Polyurethane Foam) panels, which are increasingly used in residential, commercial, and industrial projects. Their superior thermal insulation properties make them an excellent choice for reducing heating and cooling costs while supporting green building practices.

Understanding PUF Panels

These panels consist of a polyurethane foam core enclosed between two protective sheets, most often steel or aluminum, giving them the name PUF sandwich panels. This unique composition gives them high strength, durability, and, most importantly, exceptional thermal insulation capabilities. Unlike traditional construction materials such as bricks or cement, PUF panels act as a barrier against heat transfer, ensuring that indoor temperatures remain stable regardless of external weather conditions.

Role of PUF Panels in Residential Buildings

In residential spaces, heating and cooling systems typically account for a significant portion of monthly energy expenses. PUF panels minimize this expense by:

Reducing heat gain in summers – keeping interiors cooler and decreasing reliance on air conditioning.

Preventing heat loss in winters – maintaining warmer indoor spaces without excessive heating.

Creating long-term savings – homeowners experience lower electricity costs throughout the year.

Additionally, PUF panels are lightweight, easy to install, and require minimal maintenance, making them a preferred choice for modern, cost-efficient residential projects.

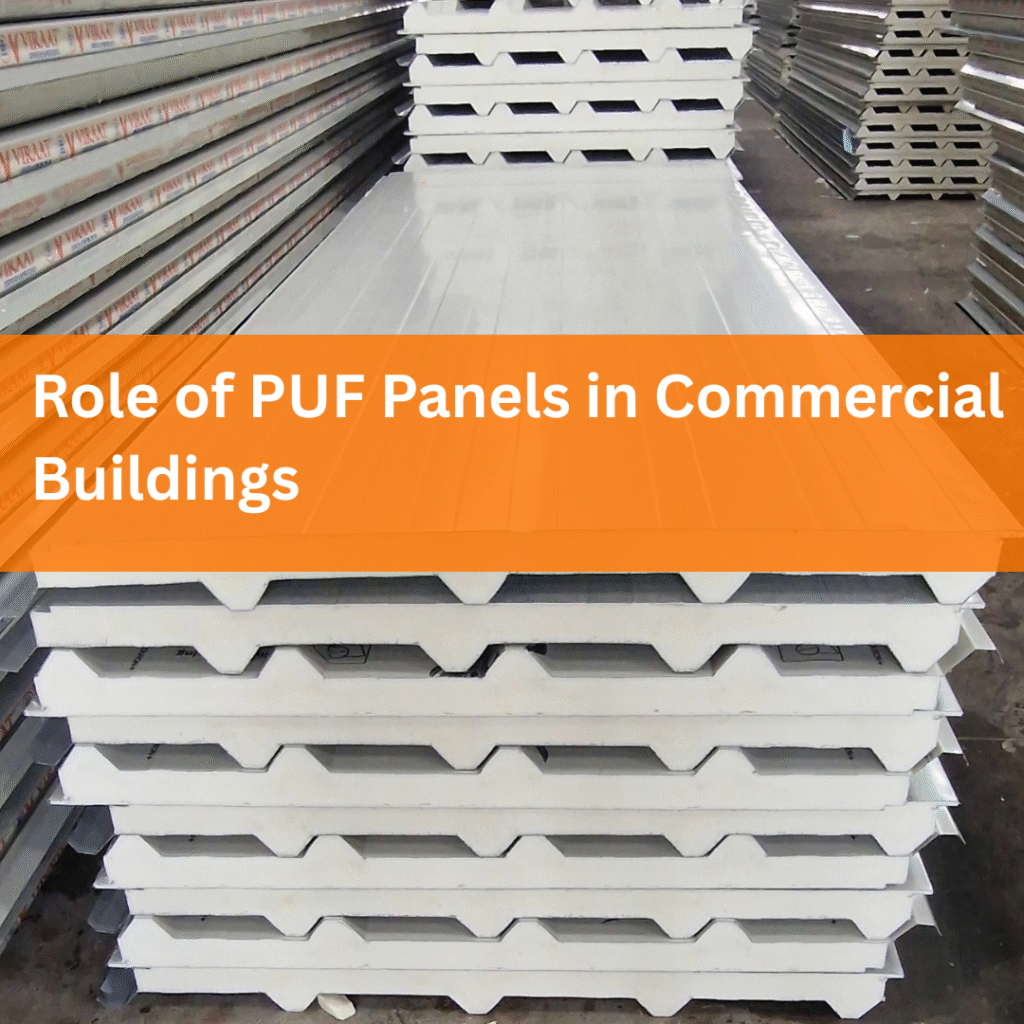

Role of PUF Panels in Commercial Buildings

Commercial spaces such as offices, shopping complexes, and educational institutions face higher energy demands due to their size and continuous usage. Here’s how PUF panels make a difference:

Improved Energy Efficiency: By maintaining consistent indoor temperatures, PUF panels reduce the load on HVAC systems.

Cost Savings for Businesses: Reduced energy bills directly benefit operational budgets.

Eco-Friendly Image: Companies adopting energy-efficient materials like PUF panels align with sustainability goals, enhancing their corporate social responsibility (CSR) efforts.

For commercial buildings, energy savings not only reduce costs but also support productivity by creating comfortable working environments.

Role of PUF Panels in Industrial Buildings

Industrial facilities such as warehouses, factories, and cold storages require strict temperature control. This is where PUF panels make a remarkable difference.

Cold Storages and Refrigerated Units: Their superior insulation ensures minimal energy loss, maintaining required temperatures with lower energy input.

Warehouses and Manufacturing Plants:

PUF panels protect against extreme external conditions, ensuring machinery and products are not affected by heat or cold.

Durability:

Their robust structure withstands harsh weather, reducing long-term maintenance costs.

By significantly reducing electricity consumption, industries save millions annually while ensuring operational efficiency.

Long-Term Financial and Environmental Benefits

Even if the starting cost of PUF panels is greater than conventional materials, the overall ROI proves to be far more beneficial. The reduced energy bills quickly offset the initial cost, and the panels’ long lifespan adds further value.

From an environmental perspective, PUF panels support green construction practices by lowering carbon emissions associated with high energy use. Builders, businesses, and homeowners using PUF panels not only save money but also contribute toward a sustainable future.

Conclusion

The role of PUF panels in reducing heating and cooling costs is undeniable across residential, commercial, and industrial buildings. Their ability to provide unmatched thermal insulation makes them one of the most efficient and sustainable construction materials available today. By lowering energy consumption, cutting operational costs, and supporting eco-friendly practices, PUF panels are shaping the future of energy-efficient construction.

Whether you are building a home, designing a corporate office, or setting up an industrial facility, investing in PUF panels ensures comfort, durability, and long-term savings.

Frequently Asked Questions

PUF (Polyurethane Foam) panels, also known as sandwich panels, consist of a rigid polyurethane foam core enveloped between two metal sheets—typically steel or aluminum

PUF panels are versatile—used in residential, commercial, and industrial applications, and consistently improve energy efficiency and indoor comfort

Viraat Industries offers a range of thicknesses (e.g., 30 mm to 120 mm). Thicker panels provide greater thermal resistance and better load-bearing capacity, making them more effective in demanding environments (e.g., cold storage, industrial buildings)

The polyurethane foam core of PUF panels provides superior insulation, preventing unwanted heat gain in summer and heat loss in winter. This efficiency lowers the demand on HVAC systems, resulting in substantial reductions in energy consumption—often by as much as 30%.