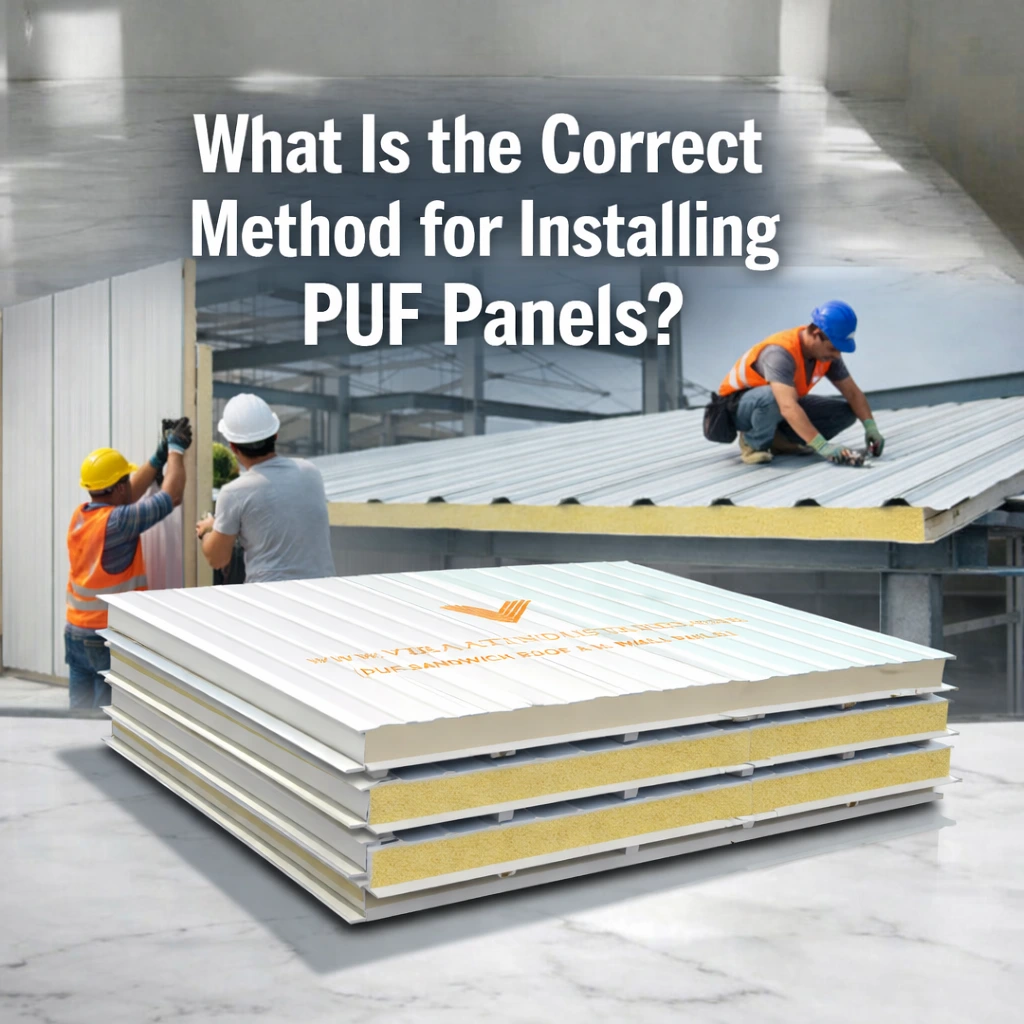

PUF panels (Polyurethane Foam Panels) have become a preferred construction solution for industrial, commercial, and cold storage buildings due to their excellent thermal insulation, lightweight structure, and fast installation. However, to achieve maximum energy efficiency, durability, and airtightness, it is essential to follow the correct method for installing PUF panels. Improper installation can lead to heat loss, air leakage, and reduced panel lifespan.

This guide explains the step-by-step installation process, best practices, and key precautions to ensure long-term performance.

Understanding PUF Panel Installation

PUF panels consist of a rigid polyurethane foam core sandwiched between two metal sheets, usually GI or PPGI. These panels are factory-manufactured and installed on-site using a dry construction method, which significantly reduces project timelines. Proper planning and execution are critical before starting the installation process.

Step-by-Step Correct Method for Installing PUF Panels

Site Inspection and Preparation

The first step in PUF panel installation is a thorough site inspection. The supporting structure—such as steel frames, purlins, or columns—must be aligned, levelled, and securely fixed. Any structural deviations can affect panel alignment and sealing.

Key checks include:

Verifying drawing dimensions

Ensuring structural members are rust-free

Confirming load-bearing capacity

A clean and obstruction-free site helps avoid installation delays and errors.

Material Handling and Storage

PUF panels must be handled carefully to prevent damage to the edges and protective coatings. Panels should be stored on a flat surface, away from moisture and direct sunlight, and covered with protective sheets.

Best practices:

Avoid dragging panels on rough surfaces

Lift panels using proper equipment

Keep panels dry before installation

Damage during handling can compromise insulation performance.

Fixing the Base Track or Starter Channel

Before installing wall panels, a base track or starter channel is fixed to the floor or plinth beam. This ensures proper panel alignment and provides a strong foundation for vertical installation.

Accurate levelling at this stage is critical, as errors can propagate throughout the structure.

Installing Wall PUF Panel

Wall panels are usually installed vertically, starting from one corner of the building. Each panel is placed into the starter channel and fixed to the structural framework using self-drilling fasteners.

Important points:

Panels should interlock tightly using tongue-and-groove joints

Fixing screws must not be overtightened

Alignment should be checked continuously

Sealant or insulation tape is applied at joints to prevent air and moisture infiltration.

Installing Roof PUF Panels

Roof panels are installed after wall panels are secured. Installation typically starts from one end of the roof and proceeds sequentially.

Key considerations:

Ensure proper slope for water drainage

Overlap panels correctly to prevent leaks

Use weather-resistant sealants at joints

Fasteners should include EPDM washers to prevent water penetration and thermal bridging.

Joint Sealing and Insulation

Proper sealing is a critical part of the correct method for installing PUF panels. All panel joints, corners, and junctions should be sealed using approved sealants or PU foam.

This step:

Improves thermal insulation

Prevents condensation

Enhances airtightness

Poor sealing is one of the most common reasons for reduced panel performance.

Installing Flashings and Accessories

Flashings are installed at panel joints, corners, roof ridges, and wall-to-roof connections. These components protect vulnerable areas from water ingress and improve the overall appearance of the structure.

Accessories may include:

Corner trims

Ridge caps

Door and window flashings

Correct installation of accessories ensures durability and a professional finish.

Quality Inspection and Final Checks

Once installation is complete, a detailed inspection is conducted to ensure:

Panels are properly aligned

Fasteners are securely fixed

Sealants are evenly applied

Any gaps or defects should be corrected immediately to avoid long-term issues.

Safety Measures During PUF Panel Installation

Safety is essential during installation, especially for roof work. Workers should use safety harnesses, helmets, gloves, and anti-slip footwear. Proper scaffolding or lifting equipment should be used to avoid accidents.

Why Following the Correct Installation Method Matters

Using the correct method for installing PUF panels ensures:

Maximum thermal efficiency

Reduced energy consumption

Longer panel lifespan

Lower maintenance costs

Correct installation also helps buildings comply with energy efficiency standards and improves indoor comfort.

Conclusion

PUF panels offer outstanding insulation and construction efficiency, but their performance depends heavily on proper installation. From site preparation and panel alignment to sealing and finishing, every step plays a crucial role in the overall process. By following the correct method for installing PUF panels, builders and project owners can achieve durable, energy-efficient, and cost-effective structures that perform reliably for years.

Frequently Asked Questions

PUF (Polyurethane Foam) panels are sandwich-type insulated panels with a rigid foam core between metal sheets. They are widely used in roofing and wall systems for industrial, commercial, and cold storage buildings due to excellent thermal insulation, lightweight structure, and fast installation.

Correct installation ensures maximum thermal efficiency, airtight sealing, long service life, and reduced energy consumption. Poor installation can lead to heat loss, air leakage, water penetration, and a reduced panel lifespan.

Begin with a site inspection and preparation: ensure the supporting structure (steel frames, purlins, columns) is aligned, levelled, and free from rust. A clean and obstruction-free site helps avoid installation errors.

Wall panels are typically installed vertically from one corner using a starter channel or base track. They must interlock tightly in tongue-and-groove joints and be fastened with self-drilling screws. Sealants or insulation tapes are applied at joints to prevent air and moisture infiltration.

Wall panels are typically installed vertically from one corner using a starter channel or base track. They must interlock tightly in tongue-and-groove joints and be fastened with self-drilling screws. Sealants or insulation tapes are applied at joints to prevent air and moisture infiltration.