PUF sandwich wall panels have become a preferred construction material across industrial, commercial, and cold storage projects due to their excellent insulation properties, durability, and ease of installation. However, one of the most critical decisions builders and architects face is choosing the right PUF sandwich panel thickness. Selecting the correct thickness directly impacts thermal efficiency, structural strength, energy savings, and overall project cost.

This guide will help builders understand how to select the ideal PUF sandwich wall panel thickness based on application, climate conditions, and performance requirements.

What Is a PUF Sandwich Panel?

PUF (Polyurethane Foam) sandwich panels consist of a rigid polyurethane foam core sandwiched between two protective metal sheets, usually galvanized steel, PPGI, or aluminum. The foam core provides excellent thermal insulation, while the outer sheets ensure strength, durability, and weather resistance.

PUF sandwich wall panels are widely used in factories, warehouses, cold rooms, clean rooms, food processing units, pharmaceuticals, and commercial buildings.

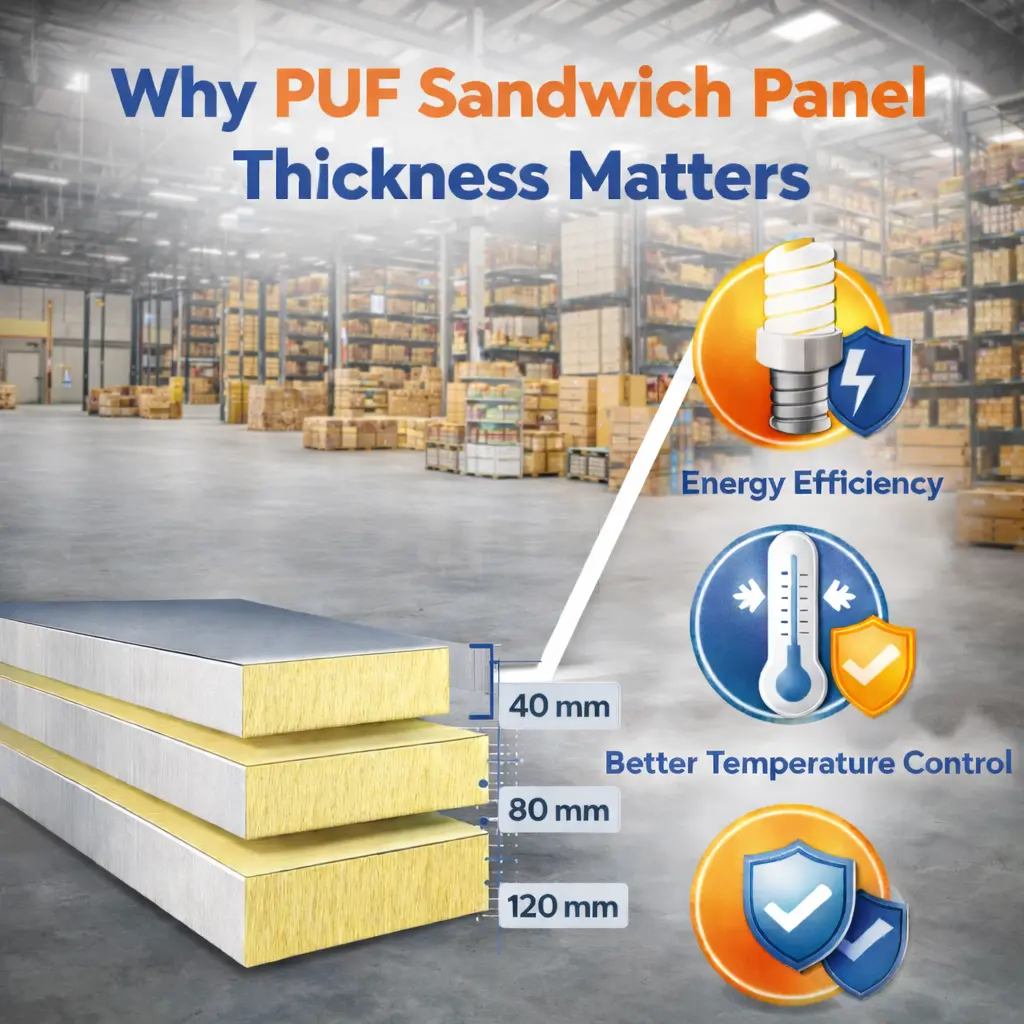

Why PUF Sandwich Panel Thickness Matters

The thickness of a PUF sandwich wall panel determines its insulation value, load-bearing capacity, and suitability for specific applications. Using panels that are too thin may lead to heat loss, condensation, or reduced durability. On the other hand, choosing excessively thick panels can increase costs unnecessarily.

Selecting the right thickness ensures:

Optimal thermal insulation

Lower energy consumption

Improved indoor comfort

Long-term structural performance

Cost-effective construction

Common PUF Sandwich Panel Thickness Options

PUF sandwich panels are available in various thicknesses to meet different building requirements. Common thicknesses include:

30 mm – Suitable for partition walls and temporary structures

40 mm – Used for light industrial and commercial interiors

50 mm – Ideal for warehouses, factories, and office buildings

60 mm – Suitable for temperature-controlled environments

80 mm – Commonly used for cold storage and food processing units

100 mm and above – Required for deep-freeze and extreme temperature control

Each thickness offers different levels of thermal resistance and strength.

Factors to Consider When Choosing PUF Sandwich Wall Panel Thickness

Application Type

The purpose of the building is the first factor to consider. For example:

Warehouses and factories generally require 50 mm to 60 mm panels.

Cold storage and refrigerated rooms often need 80 mm to 100 mm panels.

Clean rooms and pharmaceutical units may require higher thickness for temperature stability and hygiene.

Understanding the functional requirements helps narrow down the correct panel thickness.

Thermal Insulation Requirements

PUF panels are known for their low thermal conductivity. Thicker panels offer better insulation, which is essential for buildings that must maintain stable indoor temperatures.

If the project involves:

Cold storage → higher thickness is essential

Energy-efficient buildings → thicker panels reduce HVAC load

Hot or cold climatic zones → thicker panels improve comfort

Choosing the right thickness helps maintain consistent internal temperatures while reducing energy costs.

Climate Conditions

Climate plays a crucial role in determining panel thickness. In regions with extreme heat or cold, thicker PUF sandwich wall panels are recommended to prevent heat transfer.

For moderate climates, medium-thickness panels may be sufficient, while harsh weather zones require enhanced insulation to maintain indoor efficiency.

Structural Strength and Durability

While insulation is important, structural integrity should not be ignored. Thicker panels generally provide better rigidity and impact resistance, especially for large-span walls and industrial structures.

For buildings exposed to heavy wind loads or mechanical stress, choosing a thicker panel improves safety and durability.

Energy Efficiency and Cost Savings

Although thicker PUF panels have a higher upfront cost, they offer long-term savings by reducing electricity consumption. Proper insulation minimises the need for excessive heating or cooling, leading to lower operational expenses.

Builders should evaluate the return on investment rather than focusing only on initial material cost.

Compliance with Industry Standards

Different industries have specific insulation and construction standards. Cold storage, pharmaceutical, and food processing units often require panels that meet strict temperature and hygiene regulations.

Choosing the correct thickness ensures compliance with industry norms and avoids costly modifications later.

Thickness Selection for Common Applications

Application Recommended Thickness

Office & Commercial Buildings 40–50 mm

Warehouses & Factories 50–60 mm

Cold Storage 80–100 mm

Clean Rooms 60–80 mm

Food Processing Units 80 mm

Pharmaceutical Units 60–80 mm

Mistakes to Avoid When Selecting Panel Thickness

Choosing panels based only on price

Ignoring climate and insulation requirements

Using thinner panels for cold storage applications

Over-specifying thickness where it’s not needed

Proper assessment ensures the right balance between performance and cost.

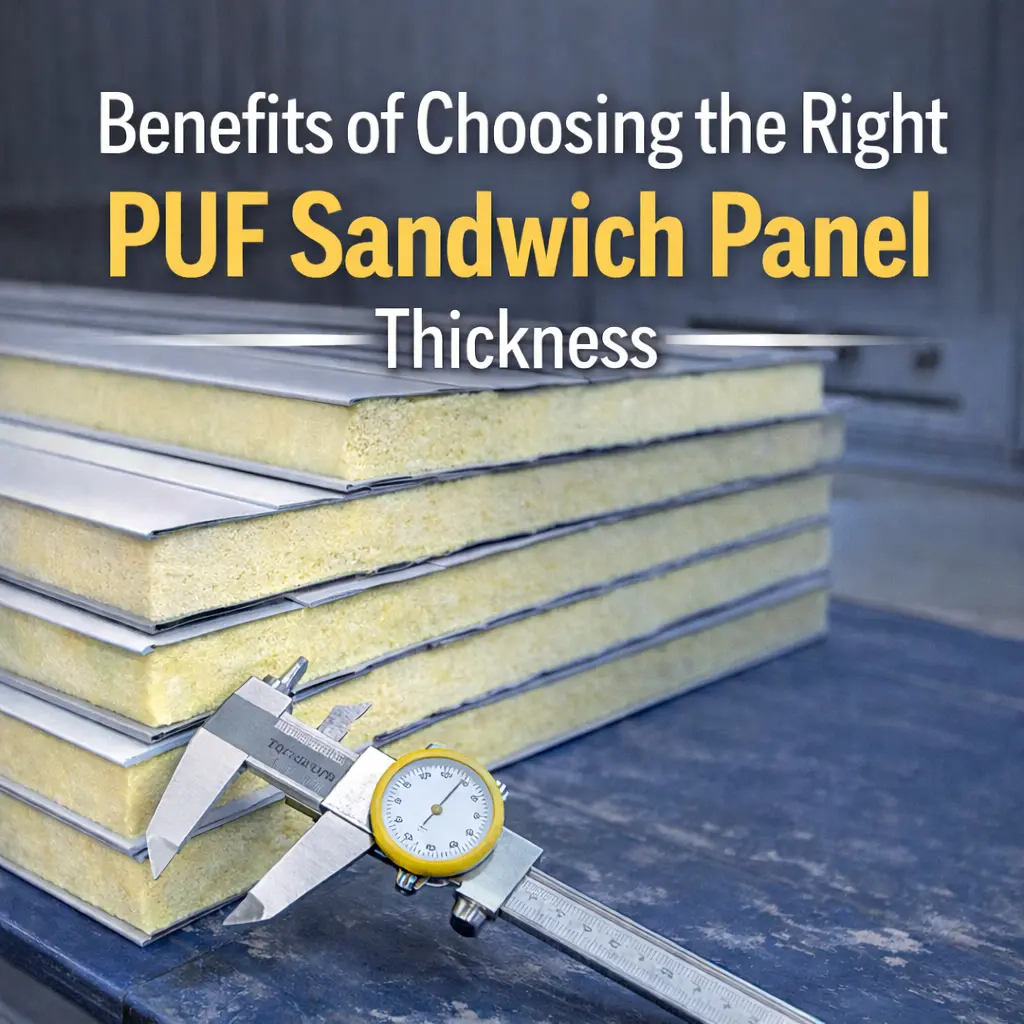

Benefits of Choosing the Right PUF Sandwich Panel Thickness

Enhanced thermal insulation

Reduced energy consumption

Long-lasting structural stability

Lower maintenance costs

Faster installation and project completion

Correct thickness selection directly improves the efficiency and lifespan of the building.

Conclusion

Choosing the right PUF sandwich wall panel thickness is a crucial decision that affects insulation performance, energy efficiency, durability, and project cost. Builders should carefully evaluate the application type, climate conditions, insulation needs, and long-term savings before finalising panel thickness.

By selecting the appropriate PUF sandwich wall panel thickness, builders can ensure high-performance structures that meet modern construction standards while delivering excellent value over time.

Frequently Asked Questions

Panel thickness directly affects thermal insulation — thicker panels provide higher R-values, which help maintain desired indoor temperatures and reduce energy costs.

In regions with extreme heat or cold, thicker panels are recommended to enhance insulation and maintain indoor comfort, whereas moderate climates may require medium thickness levels.

Yes, PUF sandwich panels can be customised to different thicknesses to match the specific performance requirements of various construction projects.

Residential, commercial, and industrial buildings have varying insulation and structural needs — for example, factory walls may require thicker panels compared to residential partition walls.