Warehouses play a critical role in modern supply chains, but outdated construction materials can lead to high energy costs, poor temperature control, and frequent maintenance issues. If you’re planning to upgrade or build a new facility, PUF sandwich panels for warehouse applications offer a smart, future-ready solution. Designed for energy efficiency, durability, and speed of installation, PUF panels are transforming industrial infrastructure across industries.

What Are PUF Sandwich Panels?

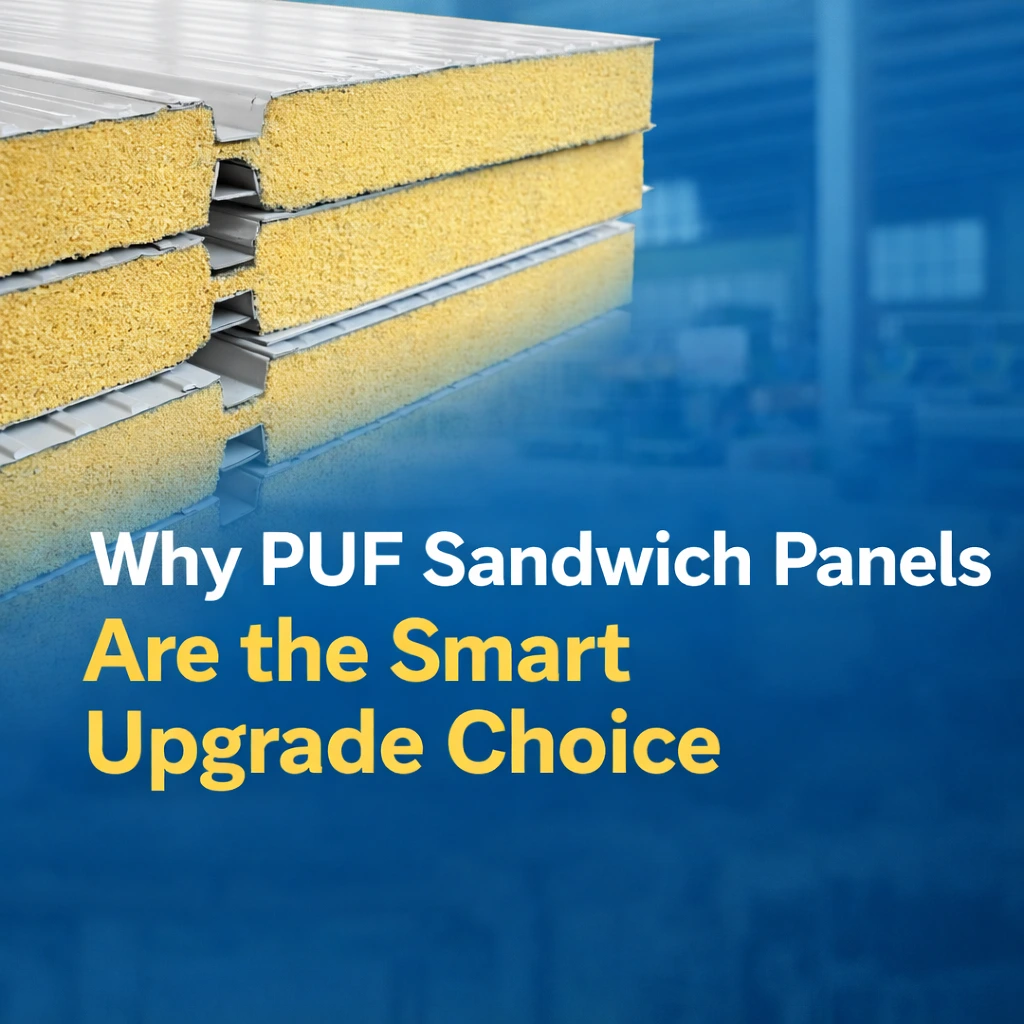

PUF (Polyurethane Foam) sandwich panels consist of a rigid polyurethane foam core sandwiched between two protective metal sheets, usually color-coated steel or aluminum. This structure creates an insulated building material that offers excellent thermal resistance, strength, and long service life.

PUF sandwich panels are widely used for warehouse walls, roofs, cold storage units, manufacturing facilities, and logistics centers where temperature stability and energy efficiency are essential.

Why Warehouses Need Advanced Insulation

Warehouses often house temperature-sensitive goods, heavy machinery, or large workforces. Without proper insulation, these spaces experience excessive heat gain, energy loss, and discomfort. Traditional construction methods like brick and concrete struggle to provide consistent insulation over large spans.

This is where PUF sandwich panels for warehouses stand out. They create a controlled indoor environment while reducing dependency on heating and cooling systems.

Key Benefits of PUF Sandwich Panels for Warehouses

Exceptional Thermal Insulation

PUF panels have one of the lowest thermal conductivity values among insulation materials. Their closed-cell foam structure prevents heat transfer, keeping interiors cooler in summer and warmer in winter. This significantly reduces energy consumption and HVAC operating costs.

Faster Construction and Installation

Time is money in warehouse projects. PUF sandwich panels are prefabricated and easy to install, reducing construction timelines by up to 40% compared to conventional methods. Faster completion means quicker operations and lower labor expenses.

Energy Efficiency and Cost Savings

One of the biggest advantages of upgrading with PUF panels is long-term savings. Reduced energy usage translates into lower electricity bills year after year. Though the initial investment may be higher, the return on investment is achieved quickly through operational efficiency.

Lightweight Yet Structurally Strong

Despite being lightweight, PUF sandwich panels offer excellent load-bearing strength. This reduces the overall structural load on the warehouse framework, allowing for cost-effective steel designs without compromising safety.

Durability and Weather Resistance

Warehouses are often exposed to harsh environmental conditions. PUF panels are resistant to corrosion, moisture, and UV radiation when paired with color-coated metal sheets. This ensures long-lasting performance with minimal maintenance.

Fire Safety Options

Modern PUF sandwich panels are available with fire-retardant properties, helping warehouses meet safety standards and building regulations. This is especially important for facilities storing flammable or high-value goods.

Hygienic and Low Maintenance

The smooth surface of PUF panels prevents dust accumulation and bacterial growth. This makes them ideal for food storage, pharmaceuticals, and FMCG warehouses where hygiene is critical. Cleaning and maintenance are simple and cost-effective.

Applications of PUF Sandwich Panels in Warehouses

PUF panels are versatile and suitable for various warehouse requirements, including:

- Logistics and distribution centers

- Cold storage and temperature-controlled warehouses

- FMCG and pharmaceutical storage

- Manufacturing and assembly units

- Agricultural produce storage

Their modular design also allows easy expansion or modification in the future.

Sustainability and Eco-Friendly Construction

With increasing focus on green buildings, PUF sandwich panels support sustainable construction goals. Their energy-saving performance reduces carbon emissions, while the metal skins are recyclable. Using PUF panels helps warehouses align with modern environmental standards and energy-efficiency certifications.

Why PUF Sandwich Panels Are the Smart Upgrade Choice

Upgrading your warehouse is not just about replacing old materials—it’s about improving performance, reducing costs, and preparing for future growth. PUF sandwich panels for warehouse construction offer a complete solution by combining insulation, durability, speed, and sustainability in one system.

From small storage facilities to large industrial warehouses, PUF panels deliver consistent performance that traditional construction methods simply cannot match.

Conclusion

If you’re ready to upgrade your warehouse, PUF sandwich panels provide a proven, cost-effective, and energy-efficient solution. With superior thermal insulation, faster installation, reduced maintenance, and long-term savings, they are an ideal choice for modern warehouse infrastructure.

Investing in PUF sandwich panels today means building a warehouse that is efficient, durable, and ready for tomorrow’s demands.

Frequently Asked Questions

PUF panels help create a controlled indoor environment with superior thermal insulation, reduced energy costs, faster installation times, and lower maintenance needs compared to traditional building materials.

Their closed-cell foam core drastically reduces heat transfer, keeping interiors cooler in summer and warmer in winter — which lowers HVAC use and leads to significant energy savings.

Yes. When paired with color-coated metal sheets, PUF panels resist corrosion, moisture, and UV exposure, ensuring long-term durability and minimal maintenance.

Absolutely. PUF panels are prefabricated and easy to install, which can significantly reduce construction timelines and labor costs compared to traditional building methods.

Yes — their excellent insulating properties make them ideal for cold storage and other temperature-sensitive warehouse environments.