Puf Sandwich Panel

Metal-faced polyurethane Sandwich Puf Panels are the system of choice of today for large industrial buildings, refrigerated warehouses, office blocks, exhibition halls, fair pavilions, schools, and sports halls. Polyurethane Sandwich Puf Panel from Viraat Industries, the leading Sandwich Puf Panels Manufacturers, comes complete with specially formed tongue-and-groove joints ensuring a perfect fit and maximum integrity. The assembly is fast, easy, and cost-effective.

Being the industry’s most reputed Sandwich Puf Panel Manufacturers, the resultant sandwich panel we manufacture is engineered with a load-bearing capability many times greater than the one achieved by adding together the load-bearing capacities of the individual layers. As a result, these thin, relatively lightweight sandwich panels can safely bridge wide spans.

With Viraat Industries, you can trust in our commitment to excellence and customer satisfaction. Our team of experts is dedicated to delivering personalized service and tailored solutions to fulfill your specific needs. We prioritize quality craftsmanship, reliability, and affordability, making us the preferred choice for sandwich puf panels in Delhi, Mumbai, and Hyderabad.

Experience the difference with Viraat Industries and elevate your projects with our exceptional sandwich puf panels. Contact us today to learn more about our products and services, and let us help you bring your vision to life with unmatched quality and innovation.

Welcome to Virat Industries, your premier destination for top-quality building materials in Mumbai and beyond. As leading puf panel manufacturers in Mumbai, we specialize in crafting innovative solutions to meet your construction needs. Our range includes puf insulated panels, designed to provide superior insulation and energy efficiency for various applications. Explore our roofing sheet manufacturing capabilities, offering durable and reliable options for your roofing projects. Whether you’re in need of insulated roof sheets or insulated puf panels, we’ve got you covered with premium products that ensure comfort and sustainability. Trust Virat Industries for all your building material requirements and experience excellence in every installation.

Specification

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm |

| Panel width available | 1070mm |

| Panel length available | 2000mm-15000mm |

| Average density | 40± 2kg/m |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| Free from CFC | CFC free |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Cubic Area Change | 1%(-30 C – 100 C/96h) |

Panel Sheets

| Polyester primer | 5 micron Non-toxic food-graded STANDARD polyester finish paint. |

| RAL 9010 color | 20 micron |

| Back coat | 5 micron |

| Resistance to saline mist | 5 micron |

| 500h (ECCA TB) | 100 h (ASTM D 2247) |

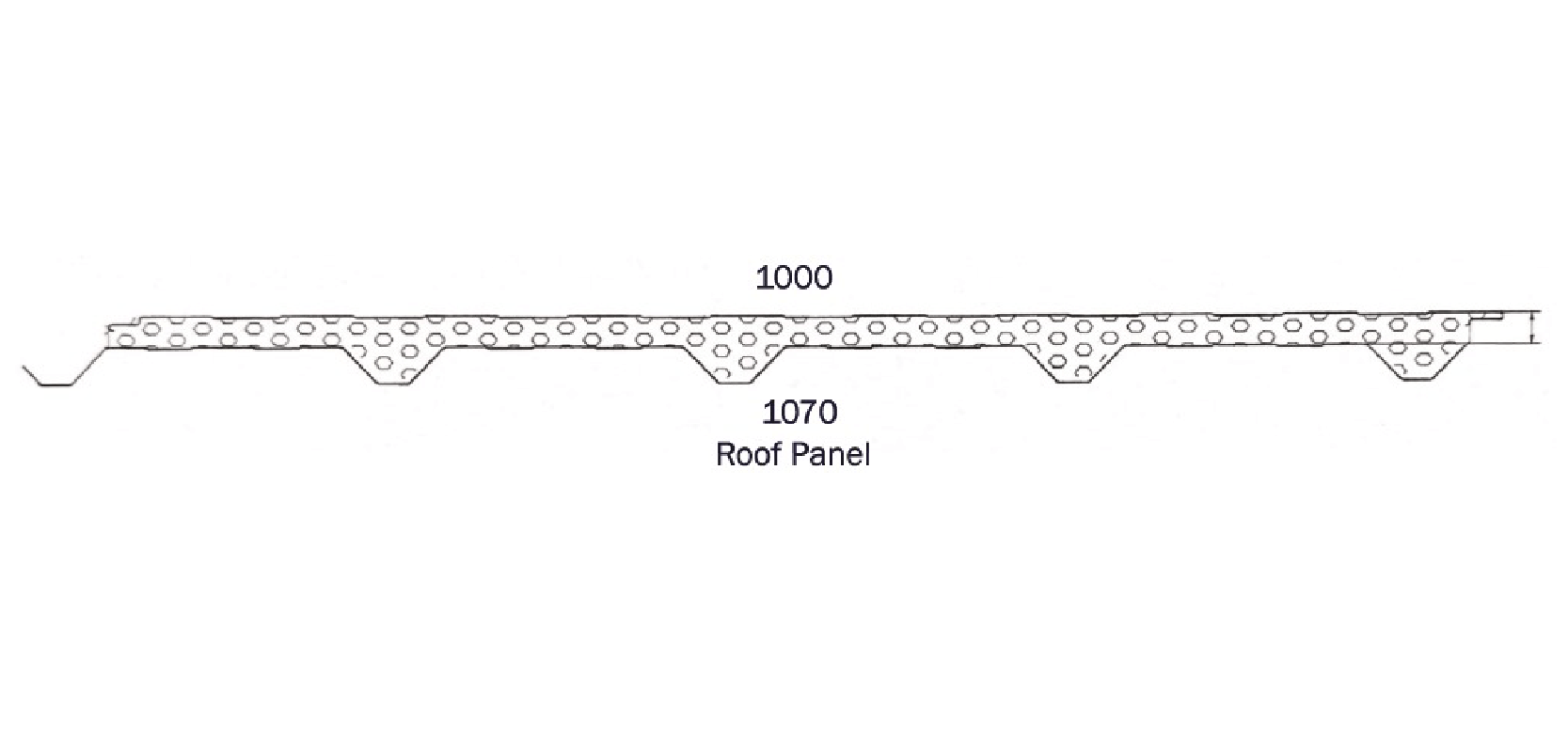

Effective Width and Length

| Wall | Roof | |

| Width | 1000 mm | 1000 mm |

| Length | 15000 mm | 15000 mm |

Advantages

As the renowned Sandwich Puf Panel Suppliers/Dealers/Wholesalers, our fabrication technique has added advantages that benefit our customers to fulfill their requirements at the best competitive price.

- Tongue and groove type joinery system.

- Hidden self tapping screws for aesthetic appeal.

- Great energy saver

- Fast and easy installation

- Light weight

- vivid colours.

- Energy conservation as per ECBC code.

Advantages Over Single Skin/Double Skin Field Insulated Panels

- High load bearing capacity at low weight.

- Excellent and durable thermal insulation.

- capacity for rapid erection without lifting equipments.

- Easier installation in hostile weather conditions.

- Easy repair and replacement in case of damage.

- Long life and very low maintenance cost

- Good sound insulation

- Reasonable fire reaction and resistance